About this deal

Steel-toed Work Boots: If you drop any materials or have any heavy equipment or tools near your feet, steel-toed boots can provide a layer of protection. To achieve optimal results, it’s essential to follow the manufacturer’s instructions closely. Gorilla Glue typically requires moisture for activation, so dampening one or both surfaces before applying the glue is recommended. Additionally, any excess glue should be promptly wiped away with a damp cloth. Uses of Copper Pipes in Plumbing Systems

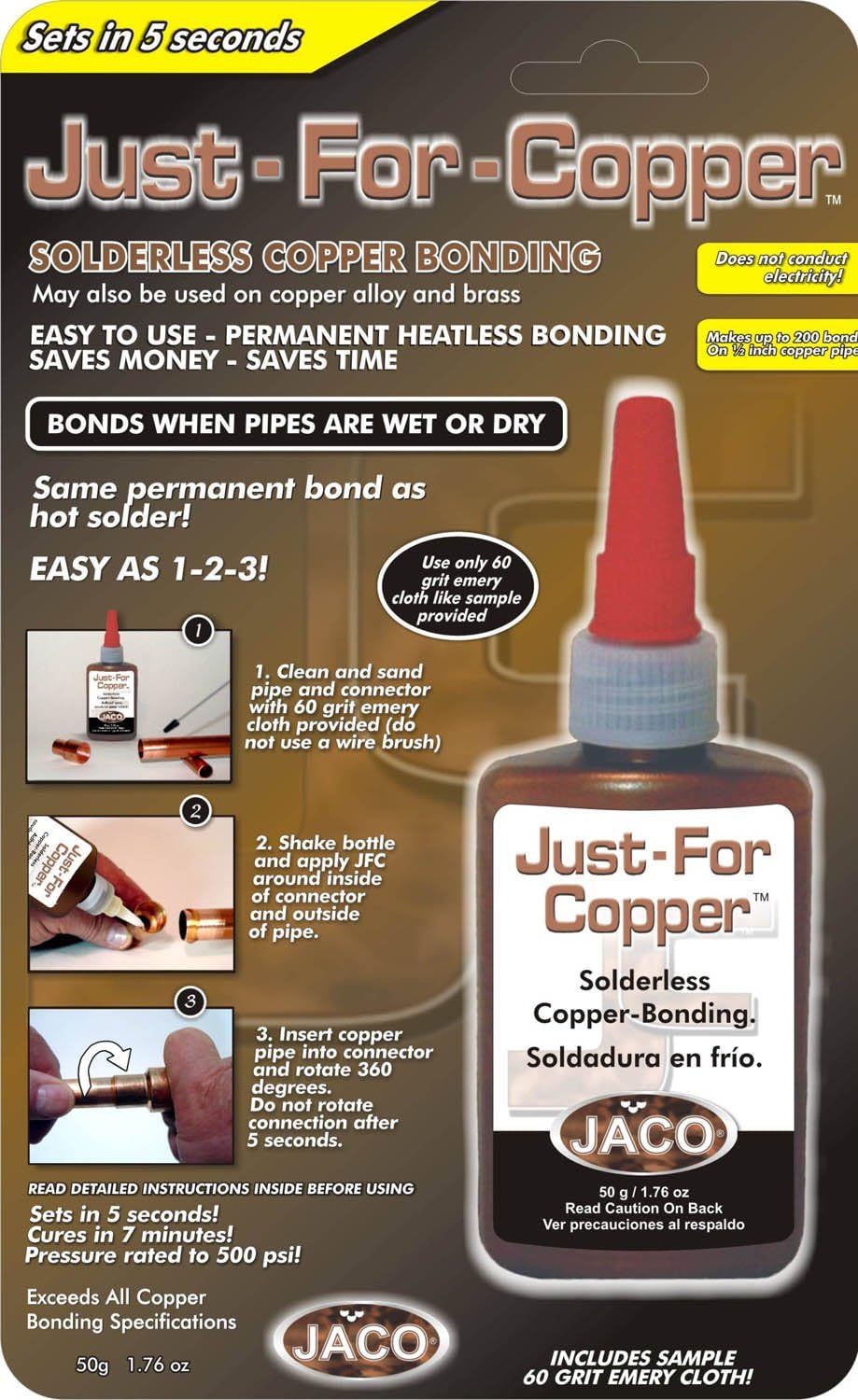

Well here’s what I found… the stuff appears to work. It certainly is a lot faster and easier than soldering (for me at least). I found that its not always possible to twist the fittings 360 deg so I did a 45 deg twist like you do with ABS. The glue does not stink (like abs-PVC glue). I did a ton of crazy up inside the wall joints and none of them leaked. I did have one leak on one fitting that I must of screwed up the application on. I think it was actually my first fitting that leaked. I drained the water line, put the glue over the leaking area and tried to blow the glue into the leak. It appears to have worked. A) Metal Water Piping. The metal water piping system shall be bonded as required in (A)(1), (A)(2), or (A)(3) of this section. The bonding jumper(s) shall be installed in accordance with 250.64(A), (B), and (E). The points of attachment of the bonding jumper(s) shall be accessible. Step 1: Apply primer to the surfaces where the adhesive will be applied. This helps to remove any dirt, debris or grease that may interfere with the bonding process. Use a clean rag to wipe off any excess primer. Allow the primer to dry for a few seconds before applying the cement. So I got a four day weekend because of turkey day. How did I spend it? Ripping out everything from out master bath and redoing the copper supply lines and ABS DWV lines..YAY! After you have finished cutting all the parts, you need to arrange the parts and accessories in the structural shape you want.Designed for use in most standard applications. It is a workable adhesive that is easy to apply and can be used for both hot and cold-water pipes. After applying adhesive and assembling the copper pipes, it is essential to allow time for the adhesive to cure properly. Curing is the process where the adhesive chemically bonds with the copper pipes, creating a strong and durable joint. In this section, we will explore the proper steps for curing and testing the joint to ensure that it is leak-free and ready for use. We will also discuss the importance of choosing the right adhesive in preventing future leaks and damages. If you are interested in gluing PVC pipes, you can read our guide on how to glue PVC pipes. Curing Time Soldering is a remarkable technique used in both plumbing and electronics to securely join metal components together. By melting a metal alloy called solder, a bond is formed between the parts being joined. Typically, solder is a combination of tin and lead, although there are lead-free alternatives available. Consider how the adhesive will be applied – whether it requires a brush, spray bottle, or application nozzle – to ensure it’s an efficient and user-friendly option for you.

In addition to cleaning and sanding the pipes, it is also necessary to clean and sand any fittings that will be used in the project. Similar to the pipes, the fittings should be scrubbed clean and roughened with sandpaper. Along with acrylic adhesives, you may use epoxy resins to glue copper. The epoxy is mixed with a hardener and applied directly to the surface that you want to bond. The components are then assembled before the epoxy fully hardens. Step 4: Repeat the process for all the remaining pipes and fittings, gradually putting your system together. The bond is very strong and is suitable for all domestic copper installations but cannot be used to cold weld other metals. It also cannot be used on threaded connectors as the joint will be too wide to prevent oxygen being present. The sketch above In summary, gluing copper pipes is a necessary skill for any DIY enthusiast or professional plumber to master. To ensure a safe and leak-free plumbing system, it is important to choose the right adhesive, prepare the copper pipes properly, and apply the adhesive correctly. Always prioritize safety precautions, such as wearing protective gear and allocating a well-ventilated workspace.Another way to connect the pipe is through soldering. In this method, you solder the copper female pipe end by applying flux. Then, you thread the copper fitting slowly over the pipe end. Subsequently, you connect the female fitting to the copper pipe. For any DIY enthusiast, soldering copper pipes is a skill that takes some time and effort to master. Fortunately, there are other methods for joining copper pipes that don’t require soldering. If you’re looking for an easier and faster way to join copper pipes without the need for a torch or solder, this blog post is for you! We’re about to walk through a step-by-step guide on how to join copper pipes without solder. Step 1: Gather Your Materials You fit ups all have to be straight-true. You can't cram a pipe into a fitting wonky and expect the glue to work. When I hot solder I often 'tweak' things to fit. No doing that with the copper glue. Once I was happy everything fit nicely, I started the glue up. I used Gorilla Original Glue. Over the different copper pipe projects I've tried this has worked the best. I find soldering holds the best, but takes too long and requires quite a bit of work to clean up the copper pipes. I have also experimented with super glue (CA Glue) which didn't hold very well.

When it comes to strength and durability, Gorilla Glue shines above the competition. It is resistant to impact and moisture, making it perfect for both indoor and outdoor projects. It can withstand extreme temperatures and remains unaffected by water or humidity once fully cured. Expanding Formula: It is not suitable for flexible pipe (such as coiled 8mm or 10mm copper heating pipe) because it cannot be guaranteed that flexible pipe will not be slightly dented, especially when cut. This means the gap between pipe and fitting might be too large for the weld to work properly. Cold copper welding requires pipe and fittings to have very close tolerances and this can only be guaranteed with rigid pipe. Wipe off excess adhesive: Use a rag to wipe off any excess adhesive that may have squeezed out of the joint. The joint should look clean and smooth. If there is still an excess of adhesive, wipe it off again until the joint looks neat. Plumbing installations and connections are definitely a great way to harness your technical skills. Although DIY installations and repairs can be helpful and fun, it may be a challenging feat if you don’t have the right materials.As you come to the end of this comprehensive guide on how to glue copper pipe, you may be feeling a mix of excitement and trepidation. On the one hand, you’re eager to see your hard work come to fruition with leak-free plumbing. On the other hand, you may have some lingering doubts or questions about whether you did everything correctly. Regardless of where you stand, it’s important to take a moment to reflect on what you’ve learned and what lies ahead. Let’s take a closer look at some key takeaways and final thoughts. Summary While this degree of resistance may prove suitable for many applications, it may not be the optimal choice for copper pipes consistently exposed to high temperatures. In such scenarios, it is advisable to utilize adhesives that are specially designed for copper pipes and possess higher temperature resistance. To ensure long-lasting and dependable results for your plumbing needs, it is advisable to seek professional assistance. Professionals employ specialized techniques such as soldering or brazing, which involve melting a metal alloy onto the joint. These methods create a strong bond that can endure high pressures and temperature fluctuations, ensuring the longevity of your copper pipes. Temperature Resistance of Gorilla Glue I can't see the problem being solved when (if) the entire branch water piping system was copper and either the SharkBite fittings or the glued joints.

Great Deal

Great Deal